Introduction to sericulture

Cultivating a Sustainable Legacy from Soil to Silk

In the realm of sericulture and weaving, we embark on a journey that transcends the ordinary, weaving threads of

tradition, innovation, and sustainable craftsmanship. From the soil to silk, this ancient art form

harmonizes with nature, fostering a connection between the earth, the silkworms, and the skilled

hands that shape the fabric of our heritage.

Sericulture begins with the nurturing of mulberry trees, creating a lush

environment for silkworms to thrive. The delicate process involves the careful cultivation of these

trees, ensuring the highest quality leaves for the silkworms. From egg to cocoon and then to silk fabric, the

meticulous stages unfold, guided by the hands of artisans dedicated to preserving the artistry of silk production.

Sustainable Development Goals (SDGs)

Sericulture aligns seamlessly with the United Nations Sustainable Development Goals, becoming a

catalyst for positive change. By promoting responsible agricultural practices, sericulture addresses

SDG 2 (Zero Hunger) through the cultivation of mulberry trees and the production of nutritious

silkworm food. SDG 8 (Decent Work and Economic Growth) is embraced through the creation of

employment opportunities, especially for women in sericulture activities.

Furthermore, sericulture contributes to SDG 15 (Life on Land) by promoting tree plantation, soil

conservation, and the overall health of ecosystems. The renewable nature of silk production aligns

with SDG 12 (Responsible Consumption and Production), emphasizing sustainability and reducing

environmental impact.

Sustainable Development Goal 5 (SDG 5) aims to achieve gender equality and empower all women

and girls. Sericulture, the ancient practice of silk production, emerges as a powerful vehicle

contributing to the realization of SDG 5 by fostering opportunities for women in various aspects of

the sericulture value chain.

Process

Cultivating the Foundation of Silk Production

A successful mulberry plantation is the cornerstone of a thriving sericulture industry, providing the nourishing environment essential for the growth and health of silkworms. The care of both soil and plants in a mulberry plantation is a meticulous process that requires dedication and expertise.

01

Site Selection and soil Preparation

To establish a mulberry plantation, choose a well-drained, sunny site with proximity to water sources for irrigation. Prepare the soil by plowing and tilling to enhance aeration, incorporating organic matter for fertility. This ensures optimal conditions for robust root development and growth of mulberry trees.

02

Pruning and Training

Pruning is a crucial aspect of mulberry tree maintenance. It involves removing dead or diseased branches and shaping the tree for optimal sunlight exposure. Proper pruning enhances air circulation, reduces the risk of diseases, and facilitates easier

harvesting.

03

Harvesting

The leaves of mulberry trees serve as the primary food source for silkworms.

Harvesting involves carefully plucking the leaves at the right stage of maturity, ensuring they

are fresh and nutritious for the silkworms. Harvesting is often done by hand to prevent

damage to the leaves.

Maintaining a mulberry plantation requires a delicate balance of scientific knowledge and traditional wisdom. The health of the soil and the well-being of the mulberry trees directly influence the success of sericulture, highlighting the interconnectedness of agriculture and silk production in the intricate tapestry of sericulture.

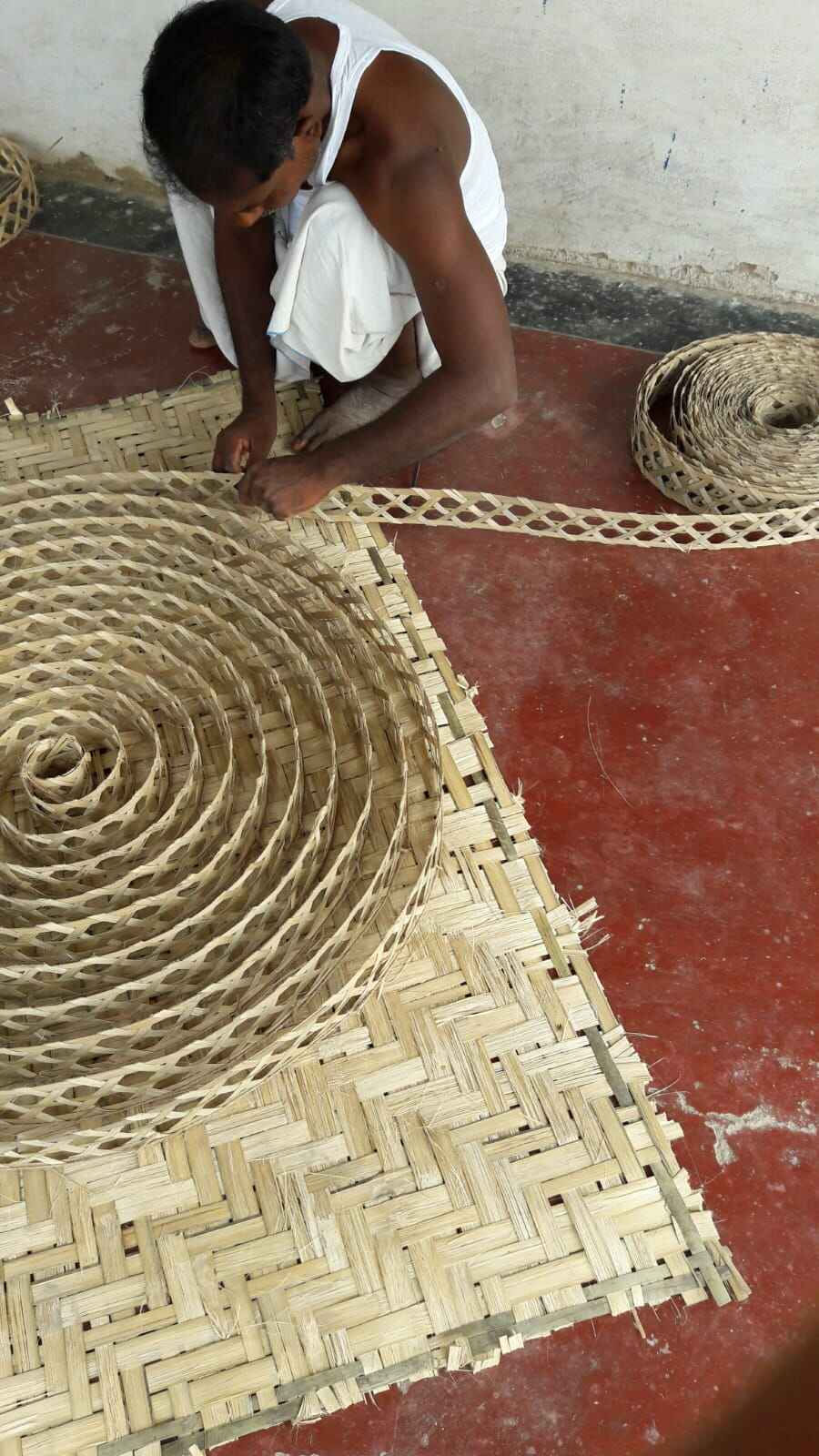

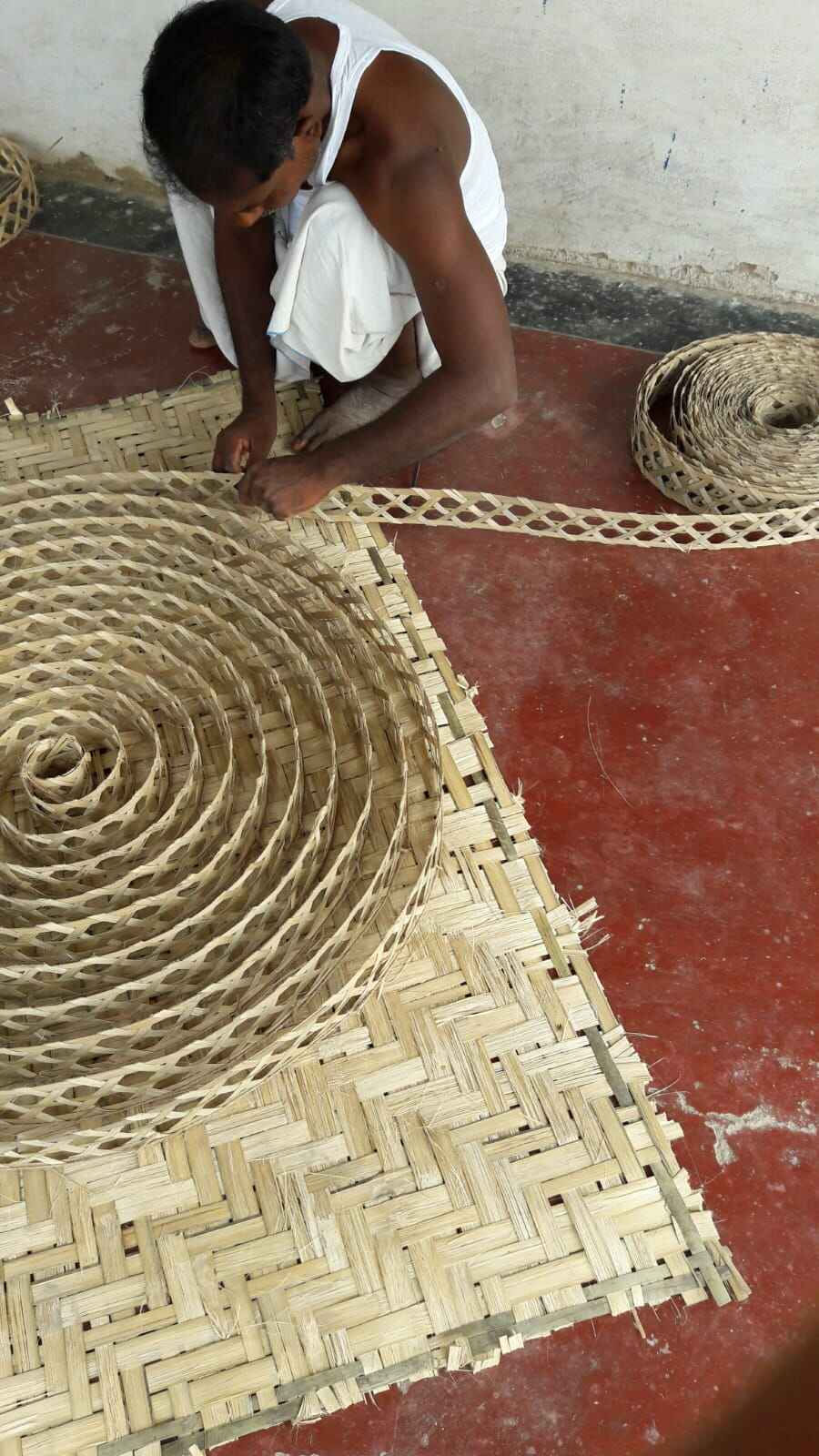

Nurturing the Silk Journey: Traditional Sericulture Practices with Bombyx mori in Rural India

In rural India, the process of sericulture is not merely a practice; it is a cultural heritage preserved through generations. The traditional tools, bamboo mats, and hands-on care represent a timeless connection to the land and a sustainable approach to silk production that weaves the fabric of rural life. The ancient art of sericulture unfolds as a harmonious symphony of nature, tradition, and meticulous care. The journey begins with the eggs of Bombyx mori, the silkworm species central to silk production, and continues through the

stages of hatching, nurturing the larvae, and tending to their transformation into silk-spinning wonders.

01

Egg Collection and Incubation

02

Hatching and Larval Care

03

Rearing and Feeding

04

Stages of Molting

The sericulture cycle commences with the collection of Bombyx mori eggs. These tiny, pearl-like orbs are delicately harvested from silk-producing farms. In traditional settings, villagers often use straw or bamboo baskets lined with soft cloth to collect and transport the precious eggs. Once collected, the eggs are incubated in controlled environments, safeguarded from harsh weather conditions.

As the eggs hatch, a spectacle unfolds as tiny silkworm larvae

emerge. This delicate stage demands utmost care, with the tiny larvae often placed on

bamboo trays or woven mats. In rural India, these mats are often crafted using traditional

bamboo-weaving techniques passed down through generations. The young silkworms, voracious eaters in their larval stage, are provided with fresh mulberry leaves, which are harvested with care from nearby plantations.

The nurturing process involves the meticulous rearing of silkworms. The sericulturalist delicately transfer the growing larvae onto fresh bamboo mats or trays, creating a conducive environment for their growth. The trays are strategically arranged to ensure proper airflow and hygiene. Silkworms feed on the tender mulberry leaves, and the caregivers carefully monitor their health, providing a steady supply of leaves and ensuring cleanliness in the rearing area.

Silkworms go through several molting stages as they shed their skin to accommodate their growing bodies. During these molting phases, villagers pay close attention to the behavior and appearance of the silkworms, adjusting temperature and humidity conditions to support their natural development. Traditional knowledge guides

this process, with experienced caregivers recognizing subtle signs of molting readiness.

05

Transition to Spinning Stage

06

Cocoon Formation

07

Harvesting and Silk Extraction

As the silkworms approach maturity, they enter the crucial

spinning stage. Traditional bamboo trays play a vital role in facilitating this transition. The mature silkworms, now seeking a suitable place to spin their cocoons, are provided with elevated platforms made of bamboo. Here, they begin the mesmerizing process of silk

thread production.

The spinning process is a marvel to behold. Silkworms exude a liquid silk

substance, creating intricate cocoons around themselves. Bamboo frames provide a natural

structure for the cocoon formation, and the caregivers ensure a serene and undisturbed

environment for this delicate stage. The silkworms spin their cocoons in a dance of silk

strands, creating a protective enclosure for their transformative journey.

Once the spinning stage is complete, the carefully crafted

bamboo trays or frames are harvested. These frames, now adorned with silk cocoons, are

gently collected. Traditional methods involve boiling or steaming the cocoons to soften the sericin, the natural protein binding the silk threads. The softened silk is then meticulously unwound, revealing the precious silk fibers that form the basis of luxurious silk fabric.

Yarn Extraction from Cocoons

In the heart of Bengal, where sericulture is an art steeped in tradition, the process of extracting yarn from silk cocoons unfolds with a timeless grace, employing the traditional Kath Ghai or wooden wheels. As the journey begins, the carefully cultivated Mulberry silk cocoons are harvested, each cocoon cocooning the potential for exquisite yarn.

The Kath Ghai, a wooden spinning wheel passed down through generations, takes centre stage in this intricate process. Skilled artisans, often with a familial legacy in silk weaving, delicately unreel the cocoon's silk threads. This labor-intensive and meticulous task requires not just technical expertise but an innate understanding of the delicate nature of silk.

The wooden wheel, with its rhythmic hum, transforms the raw silk into yarn, preserving the natural sheen and strength of the silk fibers. The process demands a gentle touch, as the artisan navigates the wheel through the cocoon, coaxing out the silk threads without

causing damage.

In Bengal, the use of the Kath Ghai or wooden spinning wheel is not just a practical method of extracting silk yarn; it is a cultural expression, a link to the past that weaves the present with threads of tradition. The resulting yarn, spun through this traditional process, becomes a testament to the enduring beauty of sericulture in Bengal, where each thread is a whisper from the loom of history.

Weaving Silk

01

Winding Yarn onto Bobbins

The journey begins with winding yarn onto bobbins, a crucial step in preparing the material for the loom.

Each yarn spool is meticulously wound onto small, manageable bobbins, ensuring uniformity and ease of handling during the looming process.

02

Warping/Drumming

Once the yarn is wound onto the bobbins, the next step is warping or drumming.

Warping involves arranging the threads systematically, often in a parallel manner, creating the foundation for the warp beam.

The warp beam, a pivotal component of the loom, holds the lengthwise yarn under tension during weaving.

03

Sizing

Sizing, also known as beaming, follows the warping process.

During sizing, the warp threads are coated with a sizing material, which may include starch or other substances. This helps to strengthen the threads and reduce friction during weaving.

04

Denting

Denting involves spacing and threading the warp threads through the reed, a comb-like device that ensures even distribution and separation of threads.

The reed is positioned in the beater, a part of the loom, and plays a crucial role in maintaining the desired density and pattern of the fabric.

05

Weaving

With the pre-loom phase complete, the weaver is ready to begin the weaving process.

The prepared warp is attached to the loom, and the weaver meticulously interlaces the weft threads through the warp using a shuttle.

The beaters help in compacting the weft threads, gradually creating the fabric according to the

drafted pattern.

The pre-loom phase, though time-consuming and labor-intensive, lays the foundation for a successful weaving process. The careful preparation of yarns, warping, sizing, drafting, and denting ensures that the subsequent weaving is a seamless and creative endeavor. Patience, skill, and attention to detail are key attributes for a weaver navigating through these intricate steps in traditional handloom weaving.